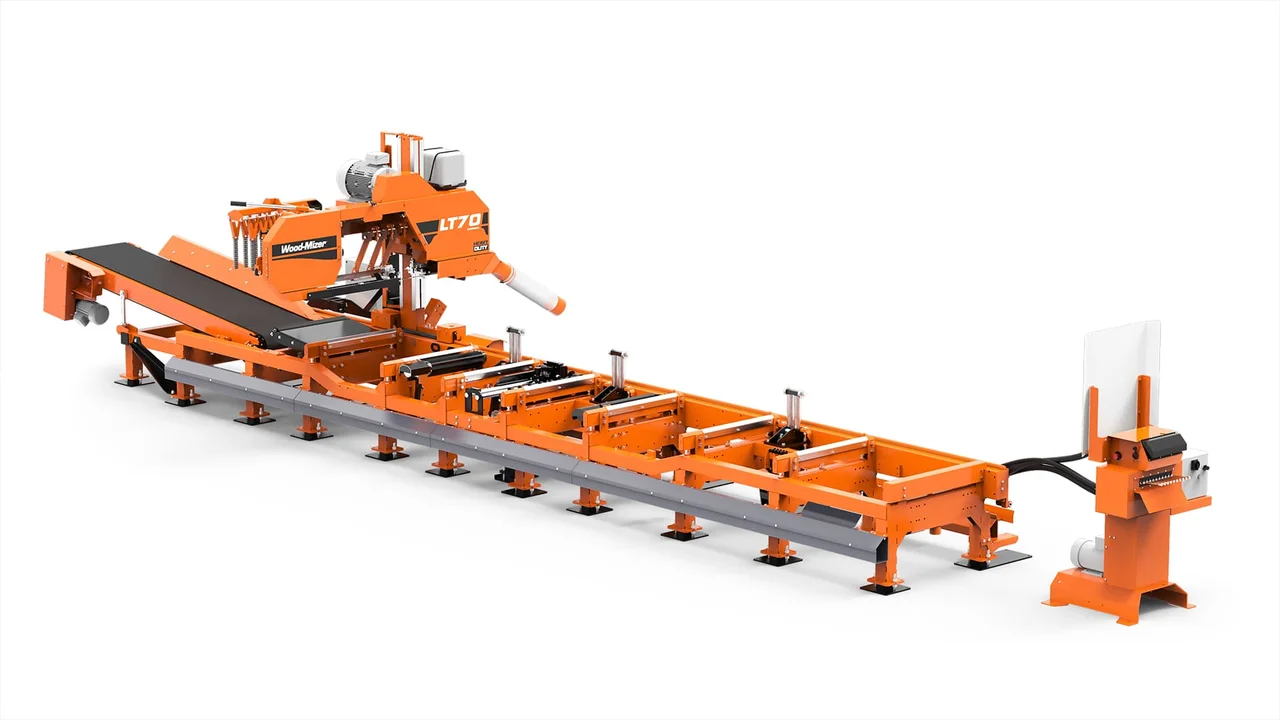

Description

The LT70 HEAVY DUTY sawmill was designed by combining the best features of the LT70 model – popular and proven for its sawing head, and the industrial WM4000 – recognized for its heavy-duty bed with Super Hydraulic log handling functions. In this high-production sawmill configuration, timber processing reaches a higher industrial-level of production efficiency and retains the ease of operation of a professional sawmill.

The cutting head is designed to saw logs up to 95 cm in diameter and offers a maximum 73 cm board width (64 cm cant width) and 39 cm depth of cut. The standard blades used in the LT70 HEAVY DUTY are 38-50 mm wide and 4670 mm long blades. The head features the Electric Blade Guide Arm for securing the blade during sawing through different sizes of logs and the Automatic Blade Lubrication for improved blade performance.

The saw head can be optionally fitted with a debarker – for removing dirt and keeping the blades sharp longer, Laser Sight – showing the precise location where the blade will cut the log next, or Board Return Arms – for transferring freshly sawn boards from the top of the log to the conveyor.

From the Remote Operator Station the sawyer controls the sawing head precisely and comfortably up/down and forward/reverse with variable speed controls. Board thickness is set up only once and the SW10 Setworks, PLC1, PLC2, or Accuset 2 takes care of resetting the head to its starting position automatically after each pass.

The HEAVY DUTY sawmills are built on a large and strong bed complete with a board removal conveyor, absorption roller and the operator’s station. For easy handling of logs as heavy as about 3 tons, the sawmiller has a Super Hydraulics Package that is powered by a heavy-duty 5.5 kW hydraulic pump and includes a log levelling roller, 3 double vertical supports, 2 power rollers on 2 cylinders, a bi-directional chain turner and a central clamp on two rods. The bed configuration can be upgraded by options such as another bed section (0.9 or 3.6 m) for handling longer logs, log-loading deck, sorting table or raised legs of the bed.