Description

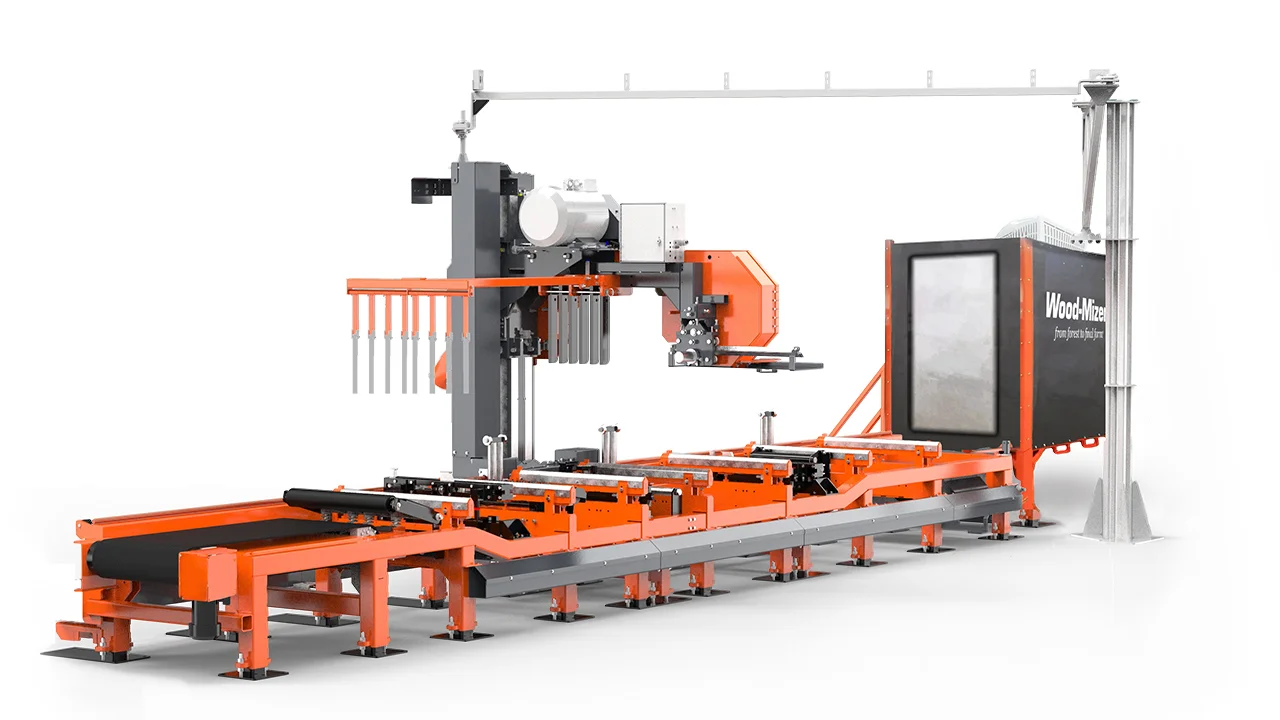

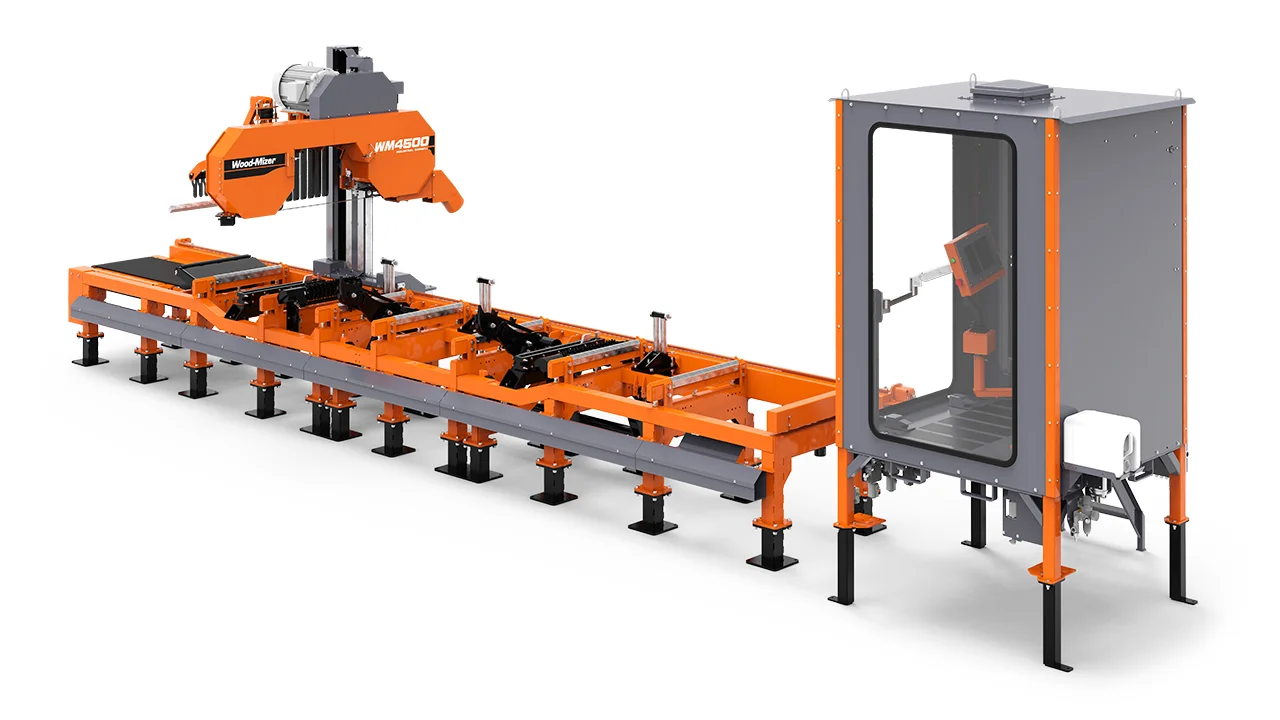

As Wood-Mizer’s next generation flagship industrial sawmill, the Wm4500 continues a long tradition of providing commercial sawmilling equipment solutions throughout the world. Featuring many benefits of Wood-Mizer’s world renowned industrial sawmill range, the WM4500 can be used as a primary headrig to saw pallet boards, grade or dimensional lumber or to breakdown logs for further processing. Alongside the complete range of Wood-Mizer sawmills, the WM4500 headrig capitalizes on thin-kerf blade technology to produce accurate lumber while reducing capital, material, labor, energy, and maintenance costs.

Key innovations of the WM4500 industrial sawmill include:

Sawmill Head

- 50.8 mm (2”) Blades with Steel Wheels

- Stronger Head, Mast, and Strain System

- New 5HP Feed Motor and Larger Up/Down Gearbox

- High Pressure Blade Lubrication System

- All New Adjustable Material Drag Back

- Longer Lasting 3” Diameter Blade Guide Rollers

Sawmill Bed

- Improved Construction & Design for Better Durability

- Reinforced Dual-Rod Side Supports

- Heavy-Duty Angled Bed Rails

- 21′ Cutting Length with Board Removal

- Pull Down Cinch Clamps for Cants

- Off-Feed Conveyor & Roller with Suspension

The WM4500 industrial sawmill is backed by the same legendary service, quality, and safety features shared by the entire family of Wood-Mizer wood processing equipment.

Production Capabilities

- Lumber – grade, dimensional, flooring, reclaimed, pallet

- Cants/beams – pallet stock, truck mats, railroad ties, timber frame, post, fencing