Description

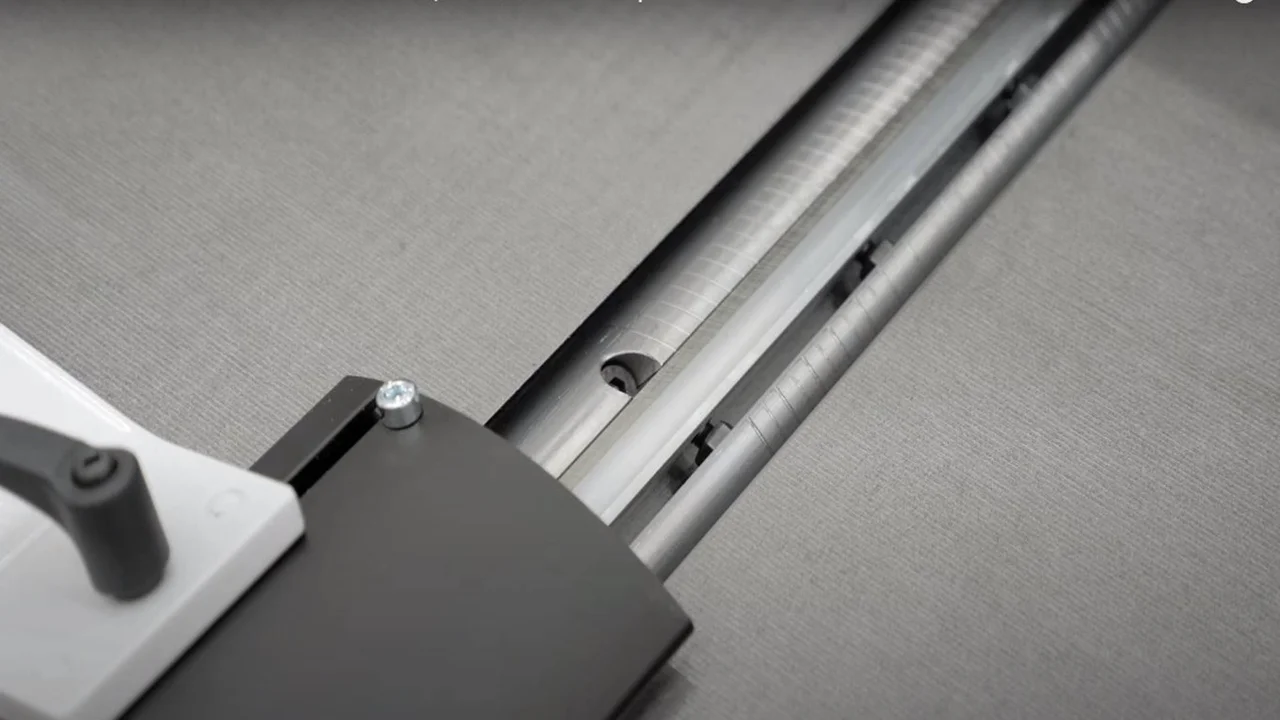

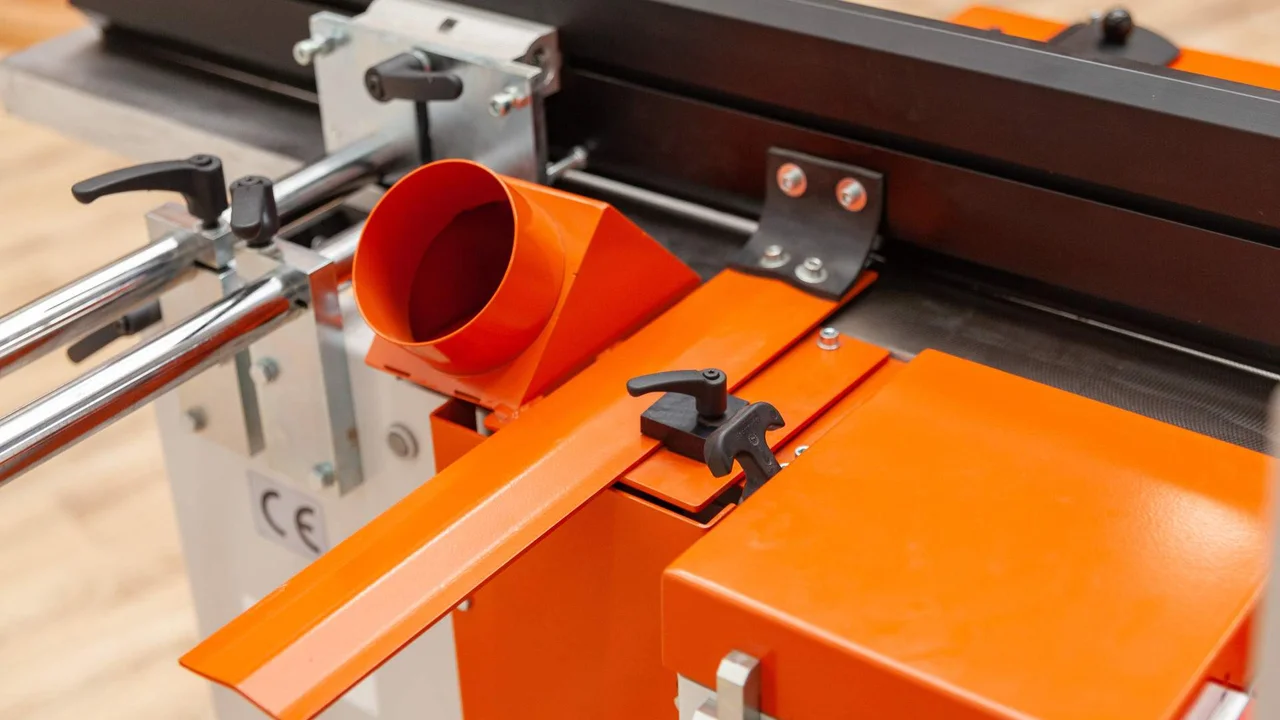

With the MP180, you have all the benefits of having a jointer and planer (planer and thicknesser) in one machine to produce flat faces and squared timber, while adding a side cutter to the lower bottom table where the planer (thicknesser) is. Take your bowed or cupped rough sawn timber and produce finished square boards and mouldings.

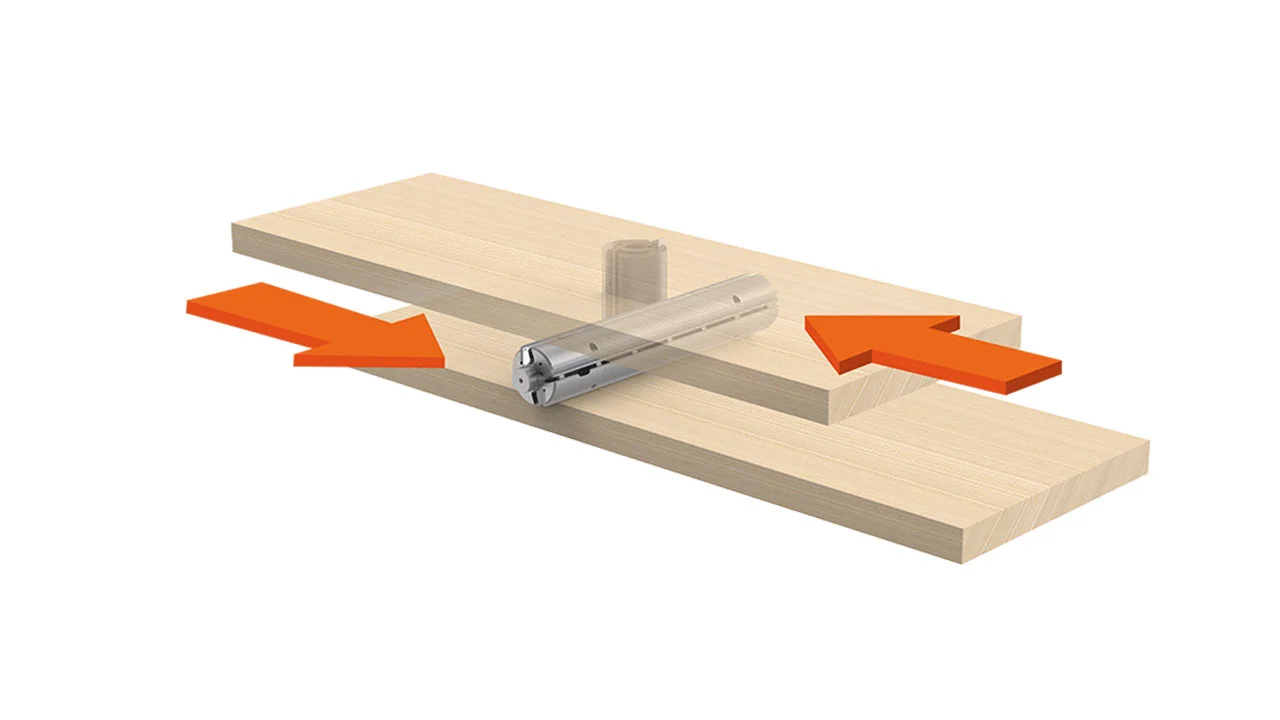

You start by using the top table for jointing (planing) – making two adjoining sides perfectly flat and at a precise right angle to each other. Then you can use the bottom table for planing (thicknessing) the last two sides at the same time, thicknessing the board to its final dimensions, and cutting down on an additional step. Moulding knives can be inserted into the side cutter, so you can also mould profiles as well. The horizontal cutter can also be fitted with profile knives with a maximum profile of 2 mm.

By utilizing the horizontal cutter for planing (thicknessing) and the vertical side cutter to mould, you can use the machine to joint, plane and mould (thickness, plane and mould) without having to reconfigure or significantly adjust the machine.

This design allows you to produce tongue and groove boards in two passes instead of the usual six to eight passes required with standard machinery. This unique combination makes the MP180 the obvious choice for carpenters who are looking for cost efficiency, versatility and precision in one machine.

The MP180 will enable you to produce high quality furniture-grade timber and mouldings.