Description

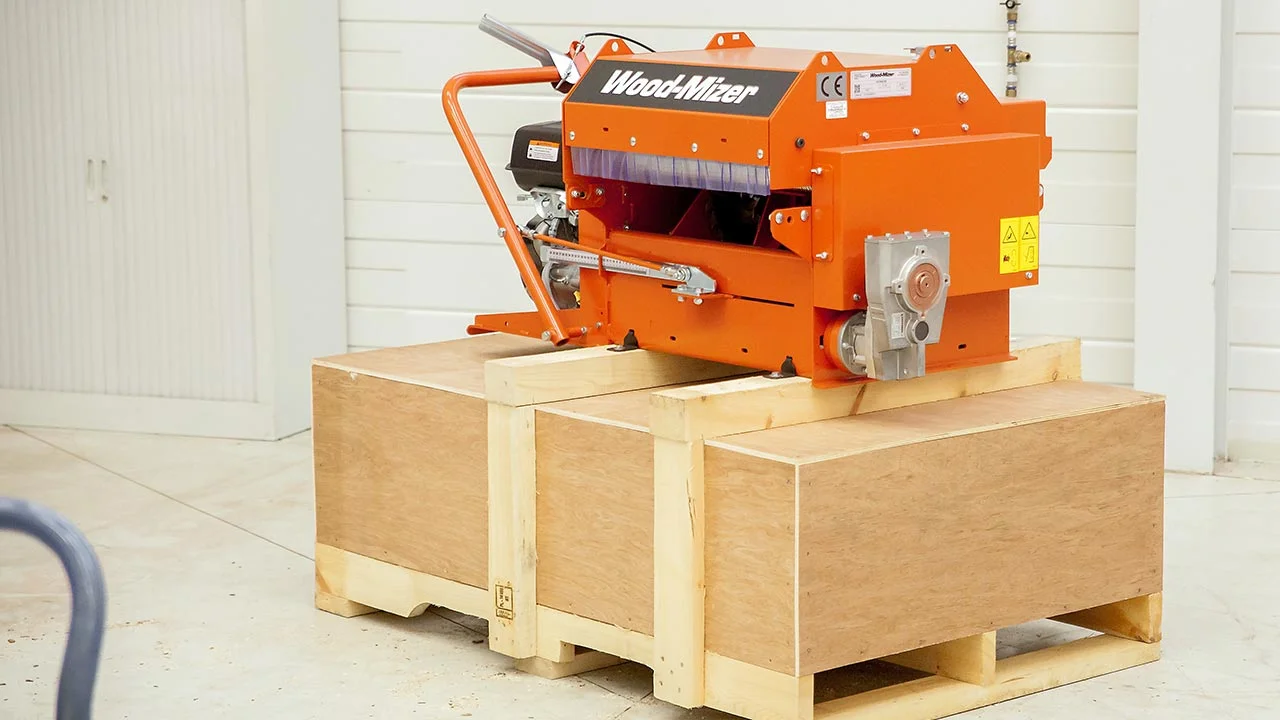

The MR200 Multirip will increase the productivity of a sawmill, as well as save time and significantly reduce the amount of work needed to rip cants. Its main purpose is to convert a cant prepared on a sawmill into a dozen high-quality boards with only one pass through the machine.

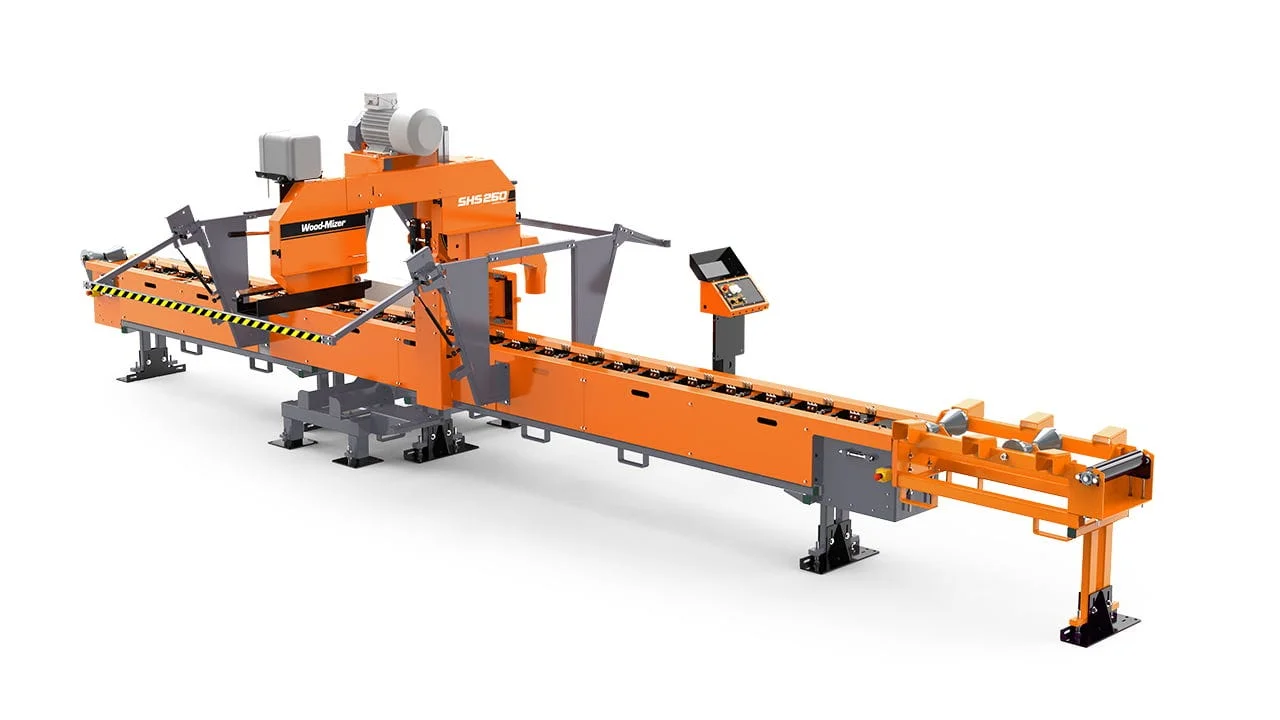

Reliability, accuracy, versatility and ease of use make the Wood-Mizer MR200 Multirip a profitable investment in medium to large sawmill production plants. The MR200 is a perfect extension of an industrial sawmilling line and works well in SLP lines or with sawmilling equipment. Its compact construction makes this machine easy to integrate into existing sawmilling lines even with limited production space. With premium quality carbide blades (e.g. WM Circular Blades) it’s possible to reach the output of 10 cubic meters of timber per hour.

The MR200 Multirip can be equipped with as many as 12 circular saws on each arbor, significantly speeding up the cant-ripping operation. Adjustable arbors (up/down) allow for higher feed speed while retaining effective and clean cutting. The maximum cant thickness for the MR200 is 200mm at the width of 450mm (standard version of the machine), or 540mm (wide version of the machine).

The operator panel is divided into two parts, each for controlling one arbor separately. This way you can save energy by turning off one of the arbors (while cutting cants below 100mm). An optional upgrade is an automatic feed speed control which can regulate throughput speed depending on the load of each arbor. Its low noise emission (below 95dB) means high comfort of operation throughout the day. In its standard version, the MR200 Multirip is powered by two 15 kW (20 HP) motors or – optional, 18.5 kW (25 HP), 22 kW (30 HP) or 30 kW (40 HP) motors.

The optional chipper that is placed before dust extraction port will minimize maintenance time while ripping cants. This investment will pay off quickly, as it will protect sawdust chutes from clogging up and forcing operators to stop the machine to clean out wooden chips, offcuts and other debris.